Have a question?

We're happy to help

TRANSPARENCY BEYOND CONFLICT FREE DIAMONDS™

We've been setting the jewelry industry's standards in transparency for nearly two decades.

Transparency is knowing where our precious metals and gemstones come from and how our jewelry is made — and sharing that information with you, so you can feel good about the jewelry you're wearing.

Beyond Conflict Free Diamonds™

Our commitment to transparency began with the Beyond Conflict Free™ standard we pioneered. We select our Beyond Conflict Free Diamonds™ for their ethical and environmentally responsible origins, surpassing the Kimberley Process (KP) standard of “conflict-free,” which is defined as diamonds that don’t fund wars against legitimate governments. Such a narrow definition, however, often ignores diamonds tainted by violence, human rights abuses, environmental destruction, and worker exploitation.

For example, Russian diamonds make up one-third of the global diamond supply and helped Russia fund its invasion of Ukraine, but they’re still considered “conflict-free” under the industry’s insufficient standard. Not to us. We stopped selling Russian diamonds the day after Russia invaded Ukraine.

In fact, less than 1% of the world’s diamonds meet our Beyond Conflict Free™ standard. Our select group of diamond suppliers must prove a robust chain of custody protocol for their diamonds, allowing us to track and sort them by origin. To meet our Beyond Conflict Free™ standard, natural diamonds must also originate only from specific mine operations or countries that demonstrate their commitment to labor, trade, and environmental standards.

Our Beyond Conflict Free Diamonds™ provide miners with fair wages and safe working conditions, empower their communities, and never fund conflicts.

Ethical Diamond Sourcing

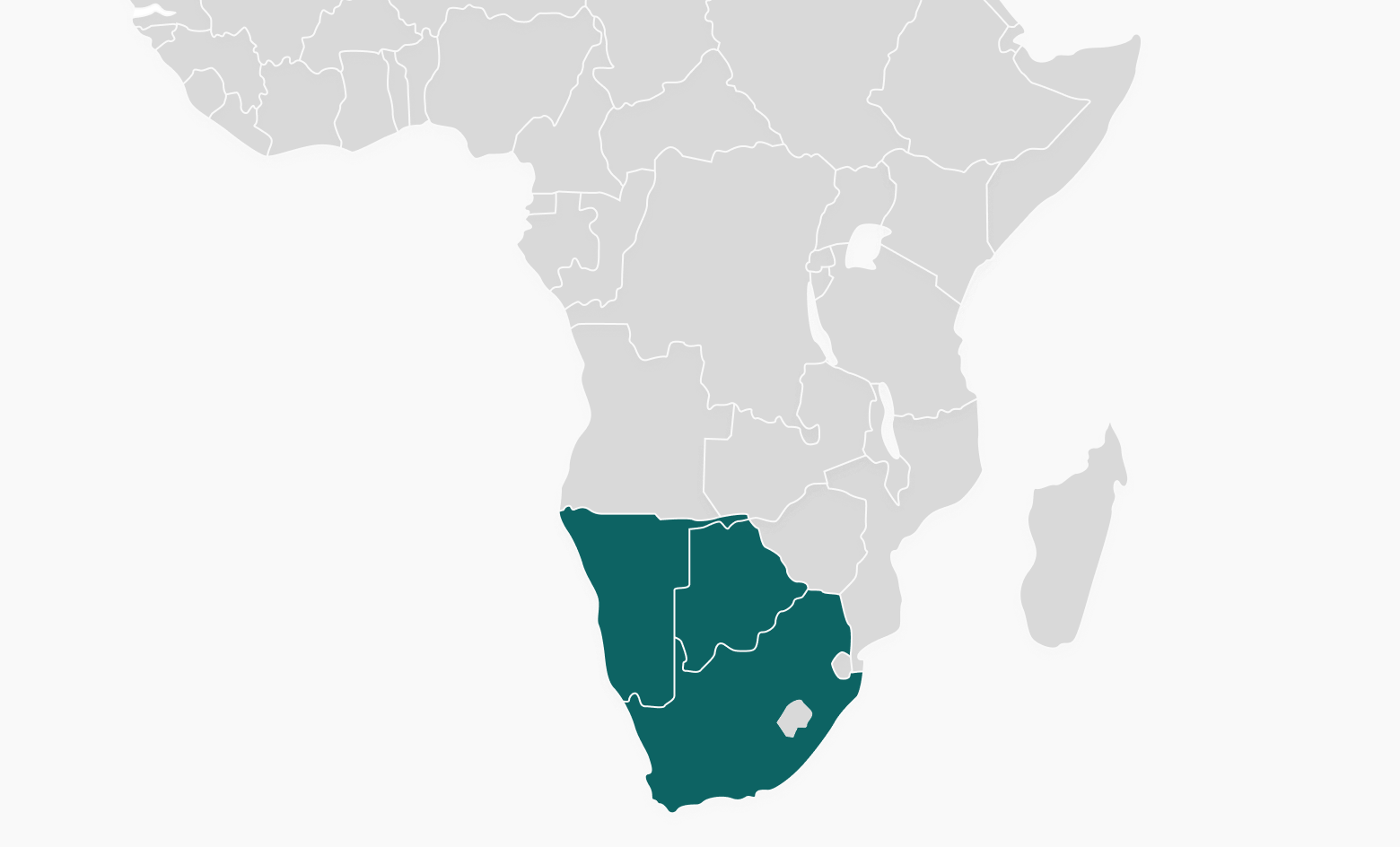

We make sure our Beyond Conflict Free Diamonds™ come from countries and mining operations that follow strict environmental rules. We source these diamonds from Botswana, Namibia, South Africa, and Canada, which are considered low or moderate risk by the Gemstones and Jewellery Community Platform Index. We're proud to sell natural diamonds that meet our Beyond Conflict Free™ standard and work with factories that are audited for safe labor practices.

Pathway to Beyond Conflict FreeTM

We currently source our Pathway to Beyond Conflict Free™ diamonds from Angola, which is known for natural diamonds of exceptional quality. Angola is actively working towards more responsible mining practices, with their largest mines already participating in transformational investments and initiatives ranging from social and environmental certifications, community programs for social and economic development, and blockchain-powered traceability. Our select group of vetted suppliers are audited for safe labor practices and strong traceability protocols.

Blockchain Diamonds

We’re revolutionizing the jewelry industry again — this time using blockchain technology. Blockchain keeps track of every step in a diamond’s journey — from mining company to market to the moment it reaches you — safely, securely, and permanently.

With our blockchain diamonds, you’ll have an enduring digital record of where your diamond comes from and how it was sourced. In 2019, we were one of the first to sell blockchain diamonds. By the end of 2023, our goal is for 20% of our diamonds to be blockchain-verified.

Conflict Free & Ethical Gemstones

We work with a small number of exclusive gemstone suppliers who share our values and source from specific countries that focus on land protection, safer mining, and improved working conditions.

We are proud of our gemstone collections that empower female artisanal miners and support fair trade markets, safer work environments, and better mining.

Where we source

Click a country on the map to learn about our Natural Diamond & Colored Gemstone Origins

Natural Diamonds

Colored Gemstones

Loading map...

Click and swipe to learn about our Natural Diamond & Colored Gemstone Origins

Natural Diamonds

Colored Gemstones

MORE ABOUT OUR MISSION

More to Explore

Conflict Free & Ethical Diamond FAQs

What is a conflict free diamond?

The Kimberley Process defines diamonds as “conflict-free” when they do not fund wars against legitimate governments.

Are conflict free diamonds real?

Yes, conflict-free diamonds are natural diamonds that do not fund wars against legitimate governments.

What is an ethically sourced diamond?

From our responsible lab diamond assortments to our transparently sourced natural diamonds, we offer a number of ways to find an ethically sourced diamond. Our Renewable Collection and Capture Collection showcase our pioneering planet-first lab diamond practices, while our Beyond Conflict Free Diamonds™ define what we consider ethical sourcing for natural diamonds: Surpassing Kimberley Process standards, our natural diamonds come from mine operations or countries that demonstrate a commitment to labor, trade, and environmental standards. An ethically sourced diamond meets high environmental standards for mining, supports social and economic development, and never contributes to violence, conflict, child labor, or forced labor.